Product Introduction

Precision Rotary Encoder

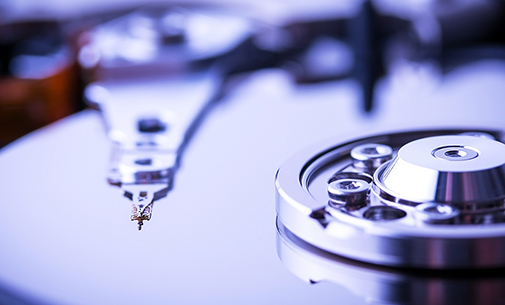

A precision rotary encoder disk is a special type of magnetic scale product, typically featuring multiple tracks (dual or multi-track), each capable of independent displacement measurement. This design allows the precision magnetic encoder disk to simultaneously measure displacement in multiple directions or dimensions, or to provide redundant measurements for enhanced accuracy and reliability. It usually incorporates advanced magnetic encoding technology and signal processing techniques to achieve high-precision displacement measurement.

Detailed Introduction

Application Advantages

High Precision: Precision magnetic encoder disks utilize advanced magnetic encoding and signal processing technologies to achieve micrometer or even nanometer-level displacement measurement accuracy. Multi-dimensional Measurement: The multi-track design enables simultaneous measurement of displacement in multiple directions or dimensions, meeting the needs of complex measurements. Redundant Measurement: Redundant measurement enhances the reliability and stability of measurements, reducing errors caused by the failure of a single measurement component. Real-time Performance: Precision magnetic encoder disks can quickly respond to changes in displacement, providing real-time position feedback for control systems. Application Fields Precision Machine Tools Workpiece Shape and Size Measurement: In precision machine tool processing, the shape and size accuracy of workpieces are crucial. Precision magnetic encoder disks can accurately measure displacement in various directions, ensuring processing accuracy. By monitoring displacement changes in real-time, the machine tool can automatically adjust processing parameters to compensate for errors caused by factors such as machine tool thermal deformation and tool wear. Multi-axis Linkage Control: In the processing of complex parts, multi-axis linkage control is often required. Precision magnetic encoder disks can measure displacement on multiple axes simultaneously, providing precise position feedback for the machine tool to achieve high-precision control of multi-axis linkage. Measurement Instruments High-precision Displacement Measurement: The high-precision characteristics of precision magnetic encoder disks make them an ideal choice for measurement instruments. In high-precision measurement equipment such as length measuring instruments and coordinate measuring machines, precision magnetic encoder disks can provide micrometer or even nanometer-level displacement measurement accuracy, ensuring the accuracy of measurement results. Multi-dimensional Displacement Measurement: Some measurement instruments need to measure the displacement of objects in multiple directions simultaneously. The multi-track design of precision magnetic encoder disks enables them to meet the needs of such measurement instruments by measuring displacement in multiple directions at the same time. Robotics Joint Angle Measurement: In robot control, accurately measuring joint angles is key to achieving precise control. Precision magnetic encoder disks can be installed at robot joints to measure changes in joint angles in real-time, providing precise position feedback for the robot controller. End Effector Position Control: The end effectors of robots (such as grippers, welding guns, etc.) require precise positioning for accurate operations. Precision magnetic encoder disks can calculate the position of the end effector by measuring the displacement of the robot arm, enabling precise control. Aerospace Assembly and Testing of Critical Components: In the aerospace field, the assembly and testing of critical components require extremely high precision. Precision magnetic encoder disks can be used to measure displacement changes during the assembly process, ensuring assembly accuracy. They can also be used to test the deformation and displacement of components under specific operating conditions, providing data support for design and optimization. Semiconductor Manufacturing Precision Positioning and Alignment: In semiconductor manufacturing, a large number of precision positioning and alignment operations are required. Precision magnetic encoder disks can be used to measure and control the position and orientation of key components such as wafers and photomasks, ensuring the precision and stability of the manufacturing process.

High Precision: Precision magnetic encoder disks utilize advanced magnetic encoding and signal processing technologies to achieve micrometer or even nanometer-level displacement measurement accuracy. Multi-dimensional Measurement: The multi-track design enables simultaneous measurement of displacement in multiple directions or dimensions, meeting the needs of complex measurements. Redundant Measurement: Redundant measurement enhances the reliability and stability of measurements, reducing errors caused by the failure of a single measurement component. Real-time Performance: Precision magnetic encoder disks can quickly respond to changes in displacement, providing real-time position feedback for control systems. Application Fields Precision Machine Tools Workpiece Shape and Size Measurement: In precision machine tool processing, the shape and size accuracy of workpieces are crucial. Precision magnetic encoder disks can accurately measure displacement in various directions, ensuring processing accuracy. By monitoring displacement changes in real-time, the machine tool can automatically adjust processing parameters to compensate for errors caused by factors such as machine tool thermal deformation and tool wear. Multi-axis Linkage Control: In the processing of complex parts, multi-axis linkage control is often required. Precision magnetic encoder disks can measure displacement on multiple axes simultaneously, providing precise position feedback for the machine tool to achieve high-precision control of multi-axis linkage. Measurement Instruments High-precision Displacement Measurement: The high-precision characteristics of precision magnetic encoder disks make them an ideal choice for measurement instruments. In high-precision measurement equipment such as length measuring instruments and coordinate measuring machines, precision magnetic encoder disks can provide micrometer or even nanometer-level displacement measurement accuracy, ensuring the accuracy of measurement results. Multi-dimensional Displacement Measurement: Some measurement instruments need to measure the displacement of objects in multiple directions simultaneously. The multi-track design of precision magnetic encoder disks enables them to meet the needs of such measurement instruments by measuring displacement in multiple directions at the same time. Robotics Joint Angle Measurement: In robot control, accurately measuring joint angles is key to achieving precise control. Precision magnetic encoder disks can be installed at robot joints to measure changes in joint angles in real-time, providing precise position feedback for the robot controller. End Effector Position Control: The end effectors of robots (such as grippers, welding guns, etc.) require precise positioning for accurate operations. Precision magnetic encoder disks can calculate the position of the end effector by measuring the displacement of the robot arm, enabling precise control. Aerospace Assembly and Testing of Critical Components: In the aerospace field, the assembly and testing of critical components require extremely high precision. Precision magnetic encoder disks can be used to measure displacement changes during the assembly process, ensuring assembly accuracy. They can also be used to test the deformation and displacement of components under specific operating conditions, providing data support for design and optimization. Semiconductor Manufacturing Precision Positioning and Alignment: In semiconductor manufacturing, a large number of precision positioning and alignment operations are required. Precision magnetic encoder disks can be used to measure and control the position and orientation of key components such as wafers and photomasks, ensuring the precision and stability of the manufacturing process.